- الرئيسية

- عن الشركة

- منتجاتنا

المنتجات والحلول

- معدات وحلول التدفئة والتهوية وتكييف الهواء

- معدات وحلول التبريد

- محركات التردد المتغير

- أدوات التحكم والملحقات في أنظمة التدفئة والتهوية وتكييف الهواء

- ملفات وأنابيب نحاسية

- قنوات وإكسسوارات التدفئة والتهوية وتكييف الهواء

- حلول القياس المتقدمة

- الخدمات وقطع الغيار

- تواصل معنا

- عملاؤنا

- العربية

- الرئيسية

- عن الشركة

- منتجاتنا

المنتجات والحلول

- معدات وحلول التدفئة والتهوية وتكييف الهواء

- معدات وحلول التبريد

- محركات التردد المتغير

- أدوات التحكم والملحقات في أنظمة التدفئة والتهوية وتكييف الهواء

- ملفات وأنابيب نحاسية

- قنوات وإكسسوارات التدفئة والتهوية وتكييف الهواء

- حلول القياس المتقدمة

- الخدمات وقطع الغيار

- تواصل معنا

- عملاؤنا

- العربية

motive ar

ATEX MOTORS

ATEX is the conventional name of the Directive 2014/34 EU for the equipment intended for use in potentially explosive atmospheres.

Motive DELPHI Ex motors differ from standard DELPHI motors because they are designed to be used, like motive “Ex” gearboxes, in the ATEX zones 1, 2, 21 and 22.

DELFIRE THREE-PHASE MOTORS

“DELFIRE” is an innovative range of three phase motors specifically designed to work in an ambient temperature of 100°C, like for instance the one of the ventilation of furnaces and dryers, in S1 continuous duty.

The used technology finds its origin in EN 12101-3 fire emergency motors for smoke evacuation, but instead of being intended for working for few hours only, it is designed to offer an S1 continuous duty service and the same lifespam of a normal motor in a normal ambient.

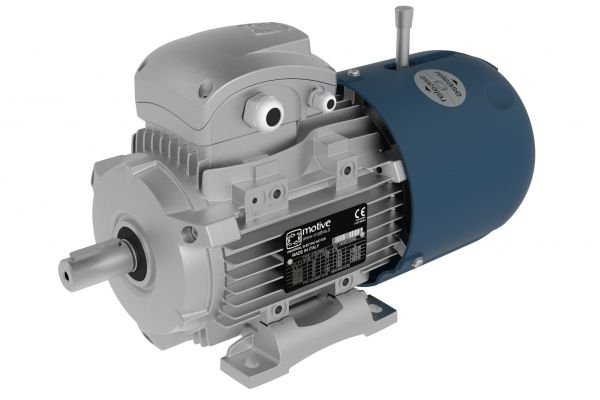

DELPHI 56-132 MOTORS

Motive motors are built according to international standard regulations;

each size throughout the construction forms is calculated with reference to the tables of standard IEC 72-1.

Motive asynchronous three-phase delphi series motors are closed, and externally ventilated.

The frame, up to 132 included, is made in die casting aluminium alloy, from size 160 up to 355 the frame is made in cast iron.

All DELPHI motors are

three-phase,

multiple voltage,

multi-frequency 50/60Hz,

F class insulation, (H on request)

S1 continuous duty service,

IP55 protection (IP56, 66 and 67 on request)

IE2, IE3 or IE4 efficiency class,

tropicalized winding

suitable for inverter power supply

IE2, high efficiency class IEC 60034-30-1

IE3, premium efficiency class IEC 60034-30-1

IE4, super premium efficiency class IEC 60034-30-1

DELPHI AT SELF-BRAKING MOTORS

Delphi ATDC, AT24 and ATTD series self-braking motors use one or 2 spring-pressure brakes, firmly spliced onto a cast iron shield at the back of the motor.

These motors include a series of characteristics normally considered options by other brands, like:

- The standard hand lever permits to release the brake, making it possible to move manually the shaft,

- The PTO thermal protectors in the winding are a standard up to size 132. PTC are a standard from size 160 and up

- Easy separate connection of the brake in case that the motor is connected to an inverter.

On ATDC and ATTD, the separate brake power supply is achieved, whenever needed, by connecting directly to the brake terminal board located inside the motor terminal box. On AT24 and ATTD24, the 24Vdc single or double brakes are designed to be directly connected to an inverter (usually having a 24Vdc plug)

On request, the brakes can be modified to be extremely silent for usage in special environments like theatres

DELPHI THREE PHASE MOTORS

Motive three phase motors from size 160 up to size 355 are made in cast iron and have all those main features of the Delphi series, among which:

• standardized dimensions according to International standards (IEC 72-1)

• multiple voltage and multi-frequency 50/60Hz,

• F class insulation, [oupon request H or H+ (delfire)]

• S1 continuous duty service,

• IP55 protection (IP56, 66 and 67 on request)

• tropicalized winding and reinforced insulation

• suitable for inverter power supply* [from 110kW and up wev recommend to order the motor with insulated barings (option)]

IE2, high efficiency class IEC 60034-30-1

IE3, premium efficiency class IEC 60034-30-1

IE4, super premium efficiency class IEC 60034-30-1

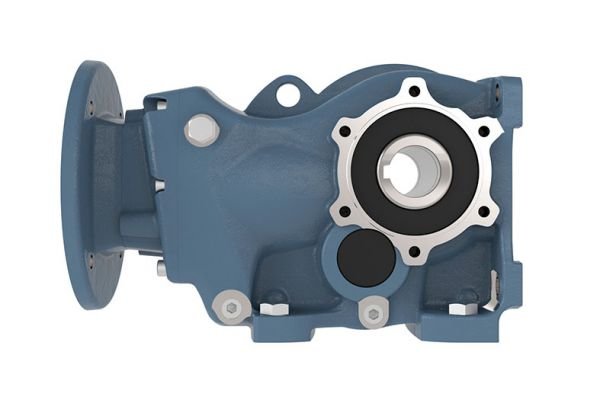

HELICAL BEVEL GEARBOX ENDURO

ENDURO is the new bevel gear reducer. In cast-iron monolithic body. 6 sizes, with a capacity of up to 4300Nm. MADE IN ITALY

MONO SINGLE PHASE MOTORS

Motive motors are built according to international standard regulations; each size throughout the construction forms is calculated with reference to the tables of standard IEC 72-1.

The frame is made in die casting aluminium alloy.

All MONO motors are single phase 230V 50Hz. On request 60Hz and special voltages F class insulation, (H on request) S1 continuous duty service, IP55 protection (IP56, 66 and 67 on request) on request extra capacitor for high starting torque

Parallel Shaft Gearbox Stone

uniquely contoured, rigid, precise, monobloc, cast iron Body, Base and flange ensure extreme robustness.

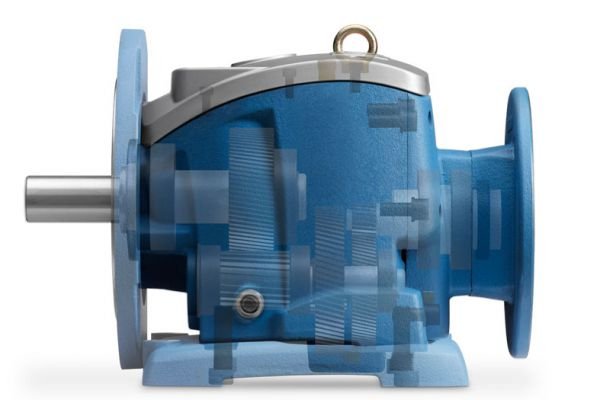

ROBUS-25-60 Inline Helical Gearbox

uniquely contoured, rigid, precise, monobloc, cast iron body, base and flange ensure extreme robustness.

modular design with detachable output flange and foot base allows easy and quick conversion between foot and flange mounting

except version a, all Robus sizes have a screw-on lifting eyebolt