Products

Low-Voltage Motors

VEM offers a comprehensive range of low-voltage motors designed to meet the diverse needs of modern industries. With a focus on energy efficiency, durability, and adaptability, these motors are engineered to deliver optimal performance across various applications.

-

Power Range: 0.06 kW to 1,000 kW, accommodating a wide spectrum of industrial requirements.

-

Efficiency Classes: Available in IE1 (Standard Efficiency), IE2 (High Efficiency), IE3 (Premium Efficiency), and IE4 (Super Premium Efficiency), ensuring compliance with international energy standards.

-

Design Variants: Offered in various mounting configurations, including IM B3, IM B35, IM B5, IM B14, and IM B34, to suit different installation needs.

-

Protection Classes: IP55 as standard, with options for IP56 and IP65, providing robust protection against dust and water ingress.

-

Cooling Methods: Equipped with self-ventilated (IC 411) or forced-ventilated (IC 416) cooling systems, ensuring optimal thermal management.

-

Construction: Rugged grey cast iron housing for enhanced durability and vibration resistance.

-

Temperature Range: Operational in environments ranging from -40°C to +60°C, suitable for various climatic conditions.

????️ Typical Applications:

VEM’s low-voltage motors are ideal for a multitude of industrial applications, including.

-

Pumps and compressors

-

Fans and ventilation systems

-

Conveyor belts and material handling equipment

-

Machine tools and processing machinery

-

HVAC systems

-

Renewable energy installations

MONO SINGLE PHASE MOTORS

Motive motors are built according to international standard regulations; each size throughout the construction forms is calculated with reference to the tables of standard IEC 72-1.

The frame is made in die casting aluminium alloy.

All MONO motors are single phase 230V 50Hz. On request 60Hz and special voltages F class insulation, (H on request) S1 continuous duty service, IP55 protection (IP56, 66 and 67 on request) on request extra capacitor for high starting torque

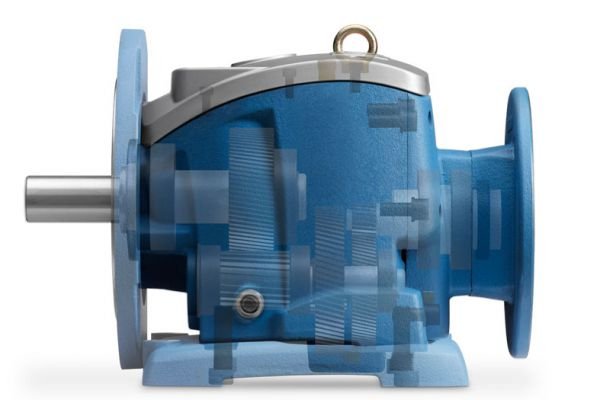

Parallel Shaft Gearbox Stone

uniquely contoured, rigid, precise, monobloc, cast iron Body, Base and flange ensure extreme robustness.

Robotics Systems – Advanced

KUKA offers a comprehensive portfolio of robotics systems designed to meet the evolving needs of modern manufacturing and automation. Their solutions encompass a wide range of robots, software, and peripheral equipment, ensuring seamless integration and optimal performance across various applications.

-

Industrial Robots: From compact models like the KR 3 AGILUS to heavy-duty robots such as the KR 1000 titan, KUKA provides robots with payload capacities ranging from 3 kg to over 1,000 kg, catering to tasks from precision assembly to heavy material handling.

-

Collaborative Robots (Cobots): The LBR iiwa series features sensitive torque sensors in all seven axes, enabling safe human-robot collaboration without the need for safety barriers.

-

Mobile Robotics: KUKA’s Autonomous Mobile Robots (AMRs), such as the KMP 1500P and KMP 3000P, offer flexible material transport solutions with payload capacities up to 3,000 kg, featuring omnidirectional movement and advanced navigation systems.

-

SCARA Robots: Designed for high-speed pick-and-place operations, KUKA’s SCARA robots deliver fast cycle times and high precision for assembly and material handling tasks.

-

Software Solutions: KUKA provides a suite of software tools, including KUKA.WorkVisual for programming and configuration, KUKA.Sim for 3D simulation and optimization, and KUKA.PLC mxAutomation for seamless integration with PLC systems.

????️ Applications:

KUKA’s robotics systems are utilized across various industries, including:

-

Automotive manufacturing

-

Electronics assembly

-

Metalworking and machining

-

Healthcare and medical device production

-

Logistics and warehouse automation

-

Consumer goods manufacturing robots.

Their robots are adept at performing tasks such as welding, handling, assembly, packaging, and quality inspection, enhancing productivity and precision in manufacturing processes.

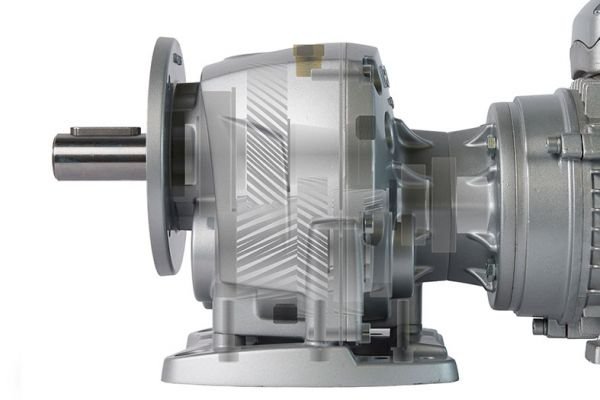

ROBUS-25-60 Inline Helical Gearbox

uniquely contoured, rigid, precise, monobloc, cast iron body, base and flange ensure extreme robustness.

modular design with detachable output flange and foot base allows easy and quick conversion between foot and flange mounting

except version a, all Robus sizes have a screw-on lifting eyebolt

ROBUS-A GEARBOXES

main body of a single piece of aluminum, for an optimal compromise between weight, rigidity and precision

a removable base, with several fixing holes, makes Robus-a interchangeable with most of the gearboxes brands

Unique construction of Robus-A makes it possible to mount any size in any position. This flexibility is achieved by: + ZZ autolubricating bearings on input and output shaft

VACON® 100 FLOW

• VACON® 100 FLOW is an AC drive that is dedicated to improving flow control and saving energy in industrial pump and fan applications.

• Supply Voltage & Power Range

– 3 x 208-240 V 0.55-90 kW

– 3 x 380-500 V 1.1-630 kW

– 3 x 525-690 V 5.5-800 kW

VACON® 100 INDUSTRIAL

• Easy-to-use and robust motor controls improve the reliability and efficiency of all AC motor types, including induction and permanent magnet and synchronous reluctance motors.

• Supply Voltage & Power Range

– 208-240 V 0.55-90 kW

– 380-500 V 1.1-630 kW

– 525-690 V 5.5-800 kW

VACON® NXC

• The enclosed VACON® NXC is the compact drive that performs reliably in harsh operating conditions in, for example, the mining, oil and gas or water and wastewater industries. The thermally managed enclosure extends drive lifetime and ensures trouble-free operation.

• Supply Voltage & Power Range

• 6- and 12-pulse supplies:

– 3 x 380-500 V 132-1200 kW

– 3 x 525-690 V 110-2000 kW

• AFE supplies:

– 3 x 380-500 V 132-1500 kW

– 3 x 525-690 V 110-2000 kW

• Low Harmonic, Active Filter supplies:

– 400 V 32-560 kW

– 500 V 132-560 kW

– 690 V 110-800 kW