Lenze

Accessories – Enhance

Lenze offers a comprehensive range of accessories designed to complement and enhance the performance of their drive solutions. These components ensure optimal functionality, energy efficiency, and seamless integration within various industrial applications.

-

Brake Resistors: Essential for applications requiring rapid deceleration, they dissipate excess energy generated during braking, protecting the system from overvoltage.

-

Mains Chokes: Reduce harmonic distortions and improve power quality by smoothing input currents, thereby enhancing the longevity of the drive system.

-

RFI and Mains Filters: Ensure compliance with EMC standards (EN 61800-3) by minimizing electromagnetic interference, crucial for maintaining system reliability.

-

Power Supply Units: Provide consistent 24V power to control electronics, ensuring uninterrupted operation even during maintenance or power fluctuations.

-

Electrical Protection Devices and Busbars: Facilitate safe energy distribution and efficient DC bus connections, optimizing energy balance and system scalability.

⚙️ Benefits:

-

Modular Integration: Accessories are designed for seamless compatibility with Lenze drives, allowing for flexible system configurations.

-

Enhanced Efficiency: Optimize energy usage and reduce operational costs through improved power management.

-

Space and Time Saving: Compact designs and easy installation processes save valuable space and reduce setup time.

-

Compliance and Safety: Meet international standards for electromagnetic compatibility and safety, ensuring reliable and secure operations.

Geared Motors – Compact

Lenze offers a comprehensive range of geared motors designed for high performance, energy efficiency, and flexibility. Whether you’re automating machinery or powering industrial systems, Lenze geared motors provide reliable and tailored drive solutions.

-

Compact & Efficient Design

Space-saving construction combined with optimal power transmission for smooth and reliable operation. -

Wide Range of Gear Types

-

Helical Gear Motors – Ideal for applications requiring high torque and smooth speed control.

-

Bevel Gear Motors – Provide angular output and high efficiency in compact designs.

-

Helical-Bevel Gear Motors – Combine torque strength and installation flexibility.

-

Helical-Worm Gear Motors – Offer high gear ratios in minimal space, with quiet and smooth operation.

-

-

Inverter Compatibility

Seamlessly integrates with Lenze frequency inverters (e.g., i510, i550, i650) for precise speed and torque control. -

Flexible Technical Specs

-

Power Range: 0.12 – 55 kW

-

Torque: 6 – 20,000 Nm

-

Gear Ratio: Up to i=4640

-

????️ Typical Applications:

Lenze geared motors are ideal for a wide array of industrial applications, such as:

-

Conveyor and handling systems

-

Packaging and filling machines

-

Pumps and fans

-

Hoists and lifting systems

-

Automated production lines

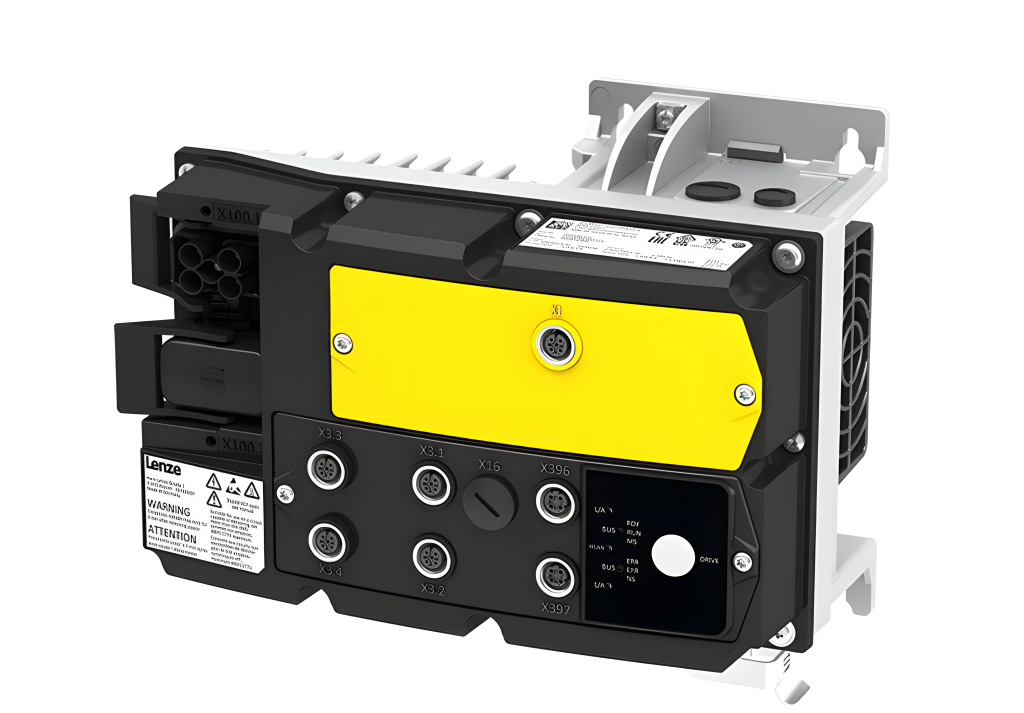

Inverters – Smart

Lenze offers a comprehensive range of inverters designed to optimize performance across various industrial applications. With modular designs and advanced control features, these inverters ensure precise motor management, energy efficiency, and seamless integration into automation systems.

-

Compact Design: Space-saving construction with widths starting from 60 mm, suitable for control cabinets with zero-clearance mounting.

-

Advanced Control Functions: Supports V/f control, sensorless vector control, and servo control with feedback, catering to diverse application needs.

-

Energy Efficiency: Equipped with energy-saving modes and regenerative braking capabilities, aligning with top efficiency classes per EN 50598-2 standards.

-

Flexible Communication: Compatible with various protocols including PROFINET, EtherCAT, EtherNet/IP, CANopen, and Modbus, ensuring easy integration into existing systems.

-

User-Friendly Interfaces: Features intuitive setup options via keypad, USB, or WLAN modules, complemented by tools like the Lenze Easy Starter and smart keypad app for efficient commissioning and diagnostics.

????️ Typical Applications:

Ideal for a wide array of industrial applications, including:

-

Conveyor and material handling systems

-

Pumps and fans

-

Packaging and filling machines

-

Hoists and lifting equipment

-

Automated production lines